Low-voltage explosion-proof string lights, engineered by Worksite Lighting, provide safe and compliant illumination for Class I Division 1 & 2 hazardous locations. Each system includes a built-in explosion-proof transformer that steps down 120V–240V input to either 12V or 24V output, minimizing the risk of arc flash in wet, enclosed, or volatile environments. These lights are purpose-built for confined space entry, marine maintenance, tank cleaning, and industrial shutdowns where standard lighting presents too much risk.

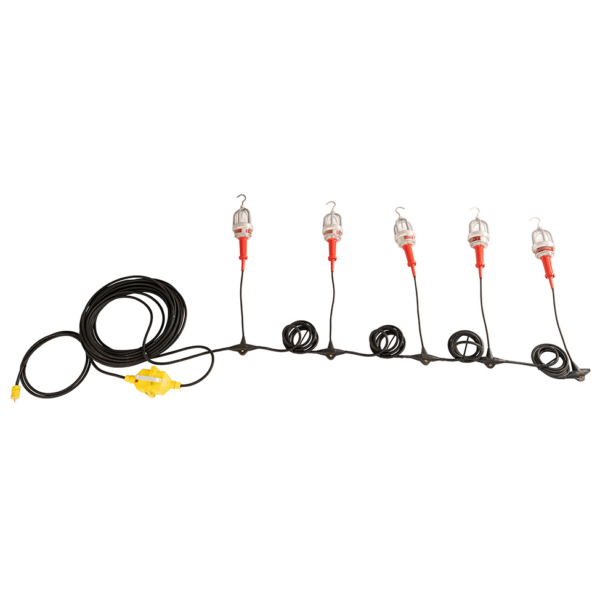

Each hand lamp delivers approximately 1,500 lumens of daylight-white light (5000K) with a 120° beam angle, ensuring broad, even coverage across your jobsite. Available in 5-, 8-, or 10-lamp configurations, the lamps are strung along a rugged SOOW cable designed to resist oil, water, abrasion, and harsh use. Factory-sealed, impact-resistant housings, NEMA 4X enclosures, and explosion-proof connectors make this system field-ready and compliant with UL844 standards for hazardous location lighting.

Setup is quick and straightforward: integrated hanging hooks on each lamp allow for rapid deployment along scaffolding, tanks, catwalks, or work zones. The transformer is plug-and-play, eliminating the need for external conversion equipment and simplifying power integration on active job sites.

Backed by a 5-year warranty, these string lights are a trusted choice for maintenance teams, contractors, and industrial crews working in hazardous areas. When your job demands low-voltage, high-reliability lighting, Worksite Lighting delivers a solution built for safety, performance, and compliance.

Reviews

There are no reviews yet