A properly rated outdoor junction box can stay submerged in water 10 meters deep and work perfectly. Protection at this level becomes significant to ensure safety and reliability when you learn about outdoor junction box applications.

The right waterproof junction box needs more than just waterproofing capabilities. Modern models come with innovative terminal wrenches that cut outdoor junction box wiring time in half. These boxes support cable sizes from Ø 0.16 to 0.39 inches (4-10 mm). Knowing which outdoor junction box connectors match your specific needs will save you time and prevent future problems.

This complete buyer’s guide will help you understand IP68 junction boxes better. We’ll cover everything from IP ratings to installation tips and give you practical advice to select the perfect solution for your outdoor electrical connections.

Understanding IP Ratings and Why IP68 Matters

The Ingress Protection (IP) rating system is an international standard that measures how well electrical enclosures resist external elements. Understanding these ratings helps ensure safety and reliability when using outdoor junction boxes.

What does IP68 mean?

Two digits in the IP rating tell you about an enclosure’s protective capabilities. The first digit shows protection against solid objects, from 0 (no protection) to 6 (complete dust-tight protection). Protection against liquids ranges from 0 to 8, shown by the second digit, where 8 means the enclosure can handle continuous immersion beyond one meter.

The “6” in an IP68 rating means the junction box is completely dust-tight. No foreign particles can get inside, which protects vital electrical connections.

The “8” shows the box’s exceptional water resistance. These boxes can stay underwater beyond one meter for long periods. Most IP68-rated boxes work perfectly after being submerged for 30 minutes to 1 hour. This makes them ideal for underground installations and flood-prone areas.

How IP68 compares to other ratings

IP67 and IP68 ratings differ mainly in how deep and how long they can stay underwater. Both keep dust out completely, but their water resistance varies by a lot. IP67-rated enclosures handle submersion up to one meter for 30 minutes. IP68 junction boxes work at greater depths beyond one meter.

Manufacturers often specify their IP68 devices can handle:

- Submersion to 1.5 meters for up to one hour

- Protection in up to 1.5 meters of fresh water for 30 minutes

Keep in mind that IP68 testing uses fresh water. Your outdoor installation might need additional protection if it faces different water types, like saltwater.

Why waterproofing is critical for outdoor use

Proper waterproofing in outdoor junction box wiring prevents serious issues. Water getting into electrical enclosures can cause short circuits, corroded terminals, and dangerous electrical failures. Water damage often means early system failure and costly repairs.

IP68-rated enclosures are a great way to get protection in many outdoor settings:

- Marine equipment and underwater lighting installations

- Outdoor and underground electrical installations in wet conditions

- Garden and landscape lighting systems near sprinklers or rain

- Solar panel systems exposed to all weather conditions

The junction box’s waterproof integrity depends heavily on its connector quality. Even IP68-rated boxes can fail if cable entries aren’t sealed properly. Using IP68-rated cable glands helps maintain the box’s protection level.

Sealing at every entry point is vital. Sealed blanking plugs must cover unused cable entry holes to keep the junction box’s protection level. Placing cable entry points on the bottom or sides of the junction box reduces water from rain or condensation.

Key Features to Look for in an Outdoor Junction Box

Your outdoor junction box selection needs more than simple protection. You should know about IP ratings and specific traits that will give reliable performance in harsh outdoor conditions.

Waterproof and dustproof sealing

The seal quality determines how well a junction box fights environmental threats. You’ll want models with strong silicone gaskets that create watertight seals between the box and lid. These gaskets should stay elastic through countless freeze-thaw cycles and won’t become brittle or crack.

Quality gasketed covers are game-changers in keeping water out, especially when you have multi-layer seals. The best protection comes from boxes with IP66 or higher ratings—IP66 confirms complete dust-tightness and resistance to strong water jets. Junction boxes with IP68 ratings protect even better by withstanding immersion up to 10 meters deep.

The main seal isn’t everything – cable entry points matter too. A perfectly sealed box becomes useless with poorly sealed cable entries. Use to keep box integrity intact, and add sealed blanking plugs for unused entry holes.IP68-rated cable glands

Material durability and UV resistance

Your outdoor junction box’s material substantially affects its lifespan and performance. Here are common materials and their advantages:

- Polycarbonate: Gives excellent impact resistance, UV stability, and flame retardancy. With a notched izod impact strength of 12 ft-lb/in and a Relative Temperature Index (RTI) rating of 221°F, polycarbonate delivers superior strength and heat tolerance.

- ABS Plastic: Delivers good impact resistance (4 ft-lb/in) but lacks UV resistance, making it unsuitable for direct sunlight applications.

- PVC: Shows good impact resistance (10 ft-lb/in) and UV stability, with an RTI rating of 185°F.

- Metal Options: Die-cast aluminum and stainless steel provide excellent durability and corrosion resistance, perfect for industrial environments or areas with harsh chemicals.

UV resistance is vital for outdoor applications since it prevents cheap materials from becoming brittle and cracked over time. Both polycarbonate and PVC resist UV well, making them ideal for outdoor electrical enclosures.

Fireproof and impact-resistant design

Safety features matter most in outdoor junction box applications. Fire resistance safeguards your electrical connections during emergencies. High-quality boxes come with UL94 5Va rating (the highest level of UL Flame Retardancy). They won’t develop burn-through holes, won’t drip burning plastic, and will self-extinguish if they catch fire.

Impact resistance helps the box handle physical shocks from falling objects or accidental strikes. The IK rating system measures this capability—aim for at least IK08, which shows the box can handle impact energy of 5 joules.

Temperature tolerance plays a key role too. Your junction boxes should work reliably in local climate extremes. The best models work in temperature ranges from -40°C to 105°C, ensuring year-round reliability.

Outdoor junction box connectors compatibility

Connector compatibility makes or breaks outdoor junction box wiring. Here’s what to look for:

- Cable diameter range: The box should fit your specific cable sizes. Quality boxes handle cables with diameters between 6-11mm.

- Multiple entry points: Boxes with dual or more cable entry points and pre-installed wire grommets give you more installation options.

- Terminal types: Ceramic terminals resist heat better, particularly in fire-rated applications. Modern boxes often include lever connectors for tool-free installation.

- Accessibility: Removable covers make maintenance and repairs easier by providing quick access to electrical connections.

Connector quality drives system reliability. Solar panel systems or garden lighting need connectors designed specifically for these environments to ensure proper sealing and electrical performance.

Choosing the Right Size and Cable Support

Accurate measurements are vital when you select and install an outdoor junction box. The right dimensions will give a proper cable fit and keep your waterproof sealing intact.

How to measure cable diameter

The right measurement stands as your first step to select suitable cable glands for outdoor junction box applications. Here’s how to measure accurately:cable diameter

- Take calipers or a wire gage tool to measure the cable’s widest part

- Write down the measurement in millimeters to match junction box specifications

- Look for any changes in cable diameter throughout its length

Cable glands work with specific diameter ranges, usually from 0.115 to 1.26 inches. Your cables must fall within this range when picking a junction box and its glands. Note that oversized glands will break the waterproof seal, while undersized ones might harm cable insulation.

Understanding cable entry points

Your outdoor junction box’s weak spots often lie at cable entry points. High-quality junction boxes offer multiple entry options with different thread types:

- Metric threads (common worldwide)

- NPT threads (standard in North America)

- PG threads (older German standard for specialized equipment)

The best protection comes from cable glands with at least IP68 rating to keep your junction box waterproof. These glands create seals that resist tugging and vibrations, which stops cable breaks and blocks potential leaks.

Well-designed entry seals let you route pre-terminated cables without connector cuts. This keeps connectivity intact and reduces EMI risks. Many models now feature self-sealing designs that block moisture.

Support for multiple cable types

Vertical installations need proper cable support to reduce strain on terminations and prevent damage. Quality cable supports must handle cable weight without damaging insulation or reducing conductor insulation where supported.

Junction boxes with removable sealing module layers work best for multiple cables. You can peel off layers until the module fits your specific cables perfectly. Space-saving entry seals can replace up to 32 traditional cable glands, which saves time during installation.

Smart planning includes picking junction boxes with extra capacity built in. This lets you add or change cables later without drilling new holes. The approach saves design time and helps avoid on-site issues with cable quantities or sizes.

Installation and Wiring Considerations

A properly installed IP68 junction box will protect its waterproof capabilities in tough outdoor environments. The right installation procedures make the difference between reliable performance and constant failures.

Tools needed for installation

You’ll need these tools ready before starting your outdoor junction box installation. Having everything at hand saves time and helps avoid quick fixes that could compromise waterproofing:

- Drill/driver with appropriate bits

- Wire stripper/cutter for precise cable preparation

- Voltage tester to ensure power is off

- Screwdrivers (flathead and Phillips)

- Fish tape for routing cables through conduit

- Silicone caulk for sealing around cable entry points

- File for creating drainage notches if needed

Safety comes first. Turn off power at the breaker before starting any electrical work. A voltage tester should confirm that circuits are dead before you handle any wires.

Outdoor junction box wiring tips

The right sealing techniques stop moisture from getting in. Waterproof cable glands should match your junction box’s IP rating to maintain protection. Silicone caulk around entry points creates watertight seals after feeding cables through the glands.

Cable preparation needs careful attention. Strip insulation with precision and leave no exposed copper outside connectors. A small “weep hole” filed at the box’s bottom edge lets condensation drain instead of building up.

Terminal types and ease of access

Junction boxes come with different terminal types that each serve specific needs:

- Screw terminals provide secure connections for larger gage wires

- Lever-action terminals allow tool-free installations

- Spring terminals offer vibration resistance

- Ceramic terminals excel in high-temperature applications

The junction box’s position should allow easy access for maintenance. Boxes with hinged covers make inspections and repairs simple without taking everything apart.

Mounting options and placement

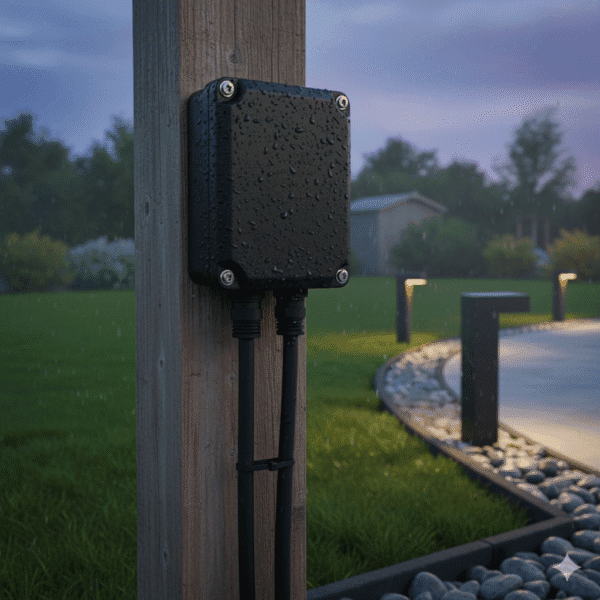

Your outdoor junction box needs smart placement and secure mounting. Wall mounting works great for buildings, while pole mounting suits lighting setups. Dedicated bracket kits adjust to pole diameters from 2″ to 12″ and keep the box firmly in place.

Areas without nearby structures might need 4×4 or 6×6 posts set in concrete for stability. The junction box should sit at least 12 inches above ground to stay dry and make maintenance easier.

The best spot for your box stays away from direct sunlight to reduce UV damage and heat. Your installation should balance easy access for servicing with a discreet fit into the landscape design.

Best Use Cases and Application Scenarios

IP68 junction boxes work great in many outdoor settings that need protection from harsh weather. You’ll make better choices when you know where these versatile enclosures work best.

Garden and landscape lighting

Garden junction boxes keep electrical connections safe from sprinklers and bad weather. These boxes started as a way to protect outdoor lighting. They stop water from getting to sensitive wiring even in heavy rain or when sprinklers are running. The boxes let you split one power feed into multiple outputs, which makes garden lighting setup much easier. They also work as homes for LED power supplies and create central control points for complex lighting systems.

Solar panel and water heater systems

The Saguaro Junction Box shows how specialized outdoor boxes help solar energy systems work better. These boxes create safe paths for electricity from solar panels. Their high voltage and current ratings work well for both big solar farms and home setups. They also blend well with energy storage systems and keep power flowing smoothly between generation and use in hybrid systems.

Billboards, signage, and road lighting

Digital billboards need junction boxes that can handle many environmental challenges. These enclosures guard against heavy rain, dust, power surges, physical damage, and temperature changes. Well-protected connections help digital displays run without problems and make quick content updates possible.

Industrial and farm equipment

Farm settings just need tough junction boxes. The equipment faces humidity, gasses, dust, water, and even curious animals that can damage electrical parts. Polycarbonate enclosures give better protection because they’re non-metallic, light, and very strong. These boxes can handle unpredictable weather like heat, UV rays, rain, sleet, hail, and snow without breaking down.

Conclusion

Your outdoor electrical connections’ safety and longevity depend on choosing the right IP68 junction box. This piece shows how good waterproofing stops expensive failures and gives reliable performance in tough conditions. IP ratings knowledge helps you make smart choices about protection levels each environment needs.

The right materials make a big difference in how long junction boxes last. Polycarbonate gives great impact resistance and UV stability, which makes it perfect for long-term outdoor use. When you match the right material with proper sealing, your connections stay safe from moisture, dust, and physical damage for years.

Cable fit is a vital part of the equation. You’ll need to measure your cables carefully before buying to make sure they fit properly in the cable glands. This step maintains waterproof integrity throughout your system and prevents common junction box failures.

The right installation methods will improve protection levels substantially. A reliable installation comes from using the right tools, following mounting guidelines, and using correct wiring practices. These steps, plus smart placement away from direct water exposure, will make your junction box last much longer.

IP68 junction boxes work well in many different settings, from garden lighting to solar setups and industrial equipment. Their reliable protection features make them key parts of any outdoor electrical system where dependability counts.

Take time to assess your environmental challenges, cable needs, and where you’ll install the box. This full picture will help you pick a junction box that gives optimal protection for your specific situation rather than a basic solution that might not work in demanding conditions.

Key Takeaways

Choosing the right IP68 junction box ensures reliable outdoor electrical connections that withstand harsh environmental conditions while maintaining safety and performance standards.

- IP68 rating provides maximum protection: Complete dust-tight sealing plus submersion resistance beyond 1 meter for extended periods, making it ideal for demanding outdoor applications.

- Material selection impacts longevity: Polycarbonate offers superior UV resistance and impact strength (12 ft-lb/in), while proper sealing mechanisms prevent moisture infiltration and system failures.

- Precise cable measurement ensures waterproof integrity: Use calipers to measure cable diameter accurately and select compatible IP68-rated cable glands to maintain the junction box’s protection level.

- Strategic installation prevents common failures: Position boxes 12+ inches above ground, use proper mounting techniques, and create drainage points to eliminate moisture accumulation.

- Versatile applications span multiple industries: From garden lighting and solar systems to industrial equipment, IP68 boxes provide essential protection for any outdoor electrical connection requiring reliable performance.

Quality junction boxes with proper installation techniques can prevent up to 90% of outdoor electrical failures caused by moisture infiltration, making the initial investment in IP68-rated equipment a cost-effective long-term solution.

FAQs

Q1. What IP rating should I look for in an outdoor junction box? For outdoor applications, look for a minimum IP rating of IP65. However, for maximum protection against dust and water immersion, an IP68 rating is ideal, as it can withstand continuous submersion beyond one meter.

Q2. How do I choose the right size junction box for my project? To determine the correct size, consider the number and size of cables you’ll be connecting, as well as any additional components that need to fit inside. Measure your cables’ diameters and ensure the box’s cable entry points can accommodate them while maintaining a proper seal.

Q3. What material is best for an outdoor junction box? Polycarbonate is an excellent choice for outdoor junction boxes due to its high impact resistance, UV stability, and flame retardancy. It can withstand harsh weather conditions and prolonged sun exposure without degrading.

Q4. Are there any special installation considerations for outdoor junction boxes? Yes, mount the box at least 12 inches above ground level to prevent water exposure. Use waterproof cable glands rated at the same IP level as your junction box, and apply silicone caulk around entry points for added protection. Also, consider creating a small drainage notch to prevent water accumulation.

Q5. Can I use an IP68 junction box for solar panel installations? Absolutely. IP68 junction boxes are well-suited for solar panel systems as they provide excellent protection against various environmental factors. They can safely house connections for electricity generated by solar panels and integrate with energy storage systems in both large-scale and residential installations.